#Counter flow induced draft

Explore tagged Tumblr posts

Text

Induced Draft Counter Flow Cooling Tower Manufacturer from India

We are the Induced Draft Counter Flow Cooling Tower Manufacturers, Suppliers, Exporters in India from Pune, Mumbai, Chennai, Bangalore, Hyderabad

#Induced Draft Counter Flow Cooling Tower Manufacturers#Induced Draft Counter Flow Cooling Tower Suppliers#Induced Draft Counter Flow Cooling Tower Exporters

0 notes

Text

Aluminium Fans Cooling Tower, Electric Motor Cooling Tower, India

Manufacturers Of Aluminium Fans Cooling Tower, Electric Motor Cooling Tower, Timber Structure Splash Bar, Water Sprinklers, Mumbai, India.

FRP, FRP Cooling Tower, F.R.P. Cooling Tower, Cooling Tower, FRP Induced Draft Cooling Tower, Timber, Timber Cross Cooling Tower, Timber Cooling Towers, Timber Draft Cross Cooling Tower, Timber Counter Flow Cooling Tower, Cooling Towers, Counter Flow Cooling Tower, R.C.C. Cooling Towers, RCC Cooling Tower, Hyperbolic Cooling Tower, RCC Mechanical Draft, Chilling Plants, Chilling Plant, Mobile Close Loop Air Cooled Chilling Plant, Open Type Water Plant,Pultruded cooling towers, Open Type Brine Chilling Plant, Brine Chilling Plant, Dehumidifier, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

0 notes

Text

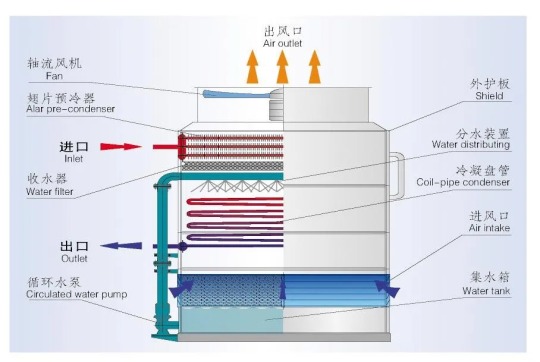

Hybrid Evaporative Cooler

A type of high-efficiency cooling device created and developed for the petrochemical sector by Longhua Technology Group (Luoyang) Company is the hybrid evaporative cooler. The high-efficiency cooler for the petrochemical industry has achieved an optimized combination of different cooling methods such as evaporative cooling, air cooling, and water cooling, thereby achieving a stable and reliable structure, extensive application scope, and obvious benefits such as energy saving, water saving, and environmental protection performance. This is based on the basic theories of latent heat exchange and sensible heat exchange.

Hybrid Evaporative Cooler Operating Principle

The hybrid evaporative cooler is similar to the three-stage series cooling system of "air cooler + water cooler + cooling water tower" combined into one set of intensive equipment, but compared with the traditional series cooling system, it has significant "three reuse processes and three differences":

1. "Three reuse processes" means that the wind and water are reused three times in the high-efficiency equipment. The first reuse of wind occurs from the lowest end of the evaporation tube to the liquid level of the water tank, in which the wind with the lowest temperature cools the circulating water falling continuously above to ensure that the water temperature in the water tank remains unchanged. The second reuse of wind occurs outside the water film of the evaporation tube, and the air with higher speed flows through the outside of the water film to form local negative pressure, which is beneficial to the evaporation of the water film and taking away the water vapor in time, thereby preventing the water vapor from forming pressure outside the water film. When the wind reaches the outside of the fin in the upward direction, the flow pattern changes from laminar flow to turbulent flow. In this state, the air heat transfer coefficient is high, the air temperature rises greatly (generally 10℃ - 15℃), and the high-temperature air is discharged from the induced-draft fan duct, thus completing the three-step cascade utilization of the air. The first cascade utilization of water also occurs at the bottom of the evaporation tube, in which water is in counter-current contact with the air inhaled from the outside for the first time. The water in torrential rain state has the function of washing, which can thoroughly flush the impurities in the air to the bottom of the water tank, ensure clean air passing through the tube bundle, and reduce scaling and blockage between the gaps of the tube bundle. The second reuse of water occurs outside the evaporation tube, and its main function is to evenly distribute the water film. It is necessary to ensure that each line of pipes and each row of pipes are evenly covered by the water film, without dry areas, and prevent scaling and corrosion under the scale. Most of the liquid water is intercepted by the water collector at the upper part of the spraying device. When saturated water vapor passes upward through the outside of the finned tube bundle, secondary interception occurs, in which saturated water vapor becomes unsaturated steam when passing through the superheated section of the fin and is discharged to the outside of the air duct, without the white mist phenomenon, and the air heat transfer coefficient outside the humidified fin is also be improved. In a series of cascade utilization, the water is reused three times, realizing "full use".

2. "Three differences" means that the equipment is quite different from the traditional air cooler, water cooler and cooling water tower. The difference between the fin section of the equipment and the fin section of the air cooler is the difference in anticorrosion. The traditional air cooler generally operates in dry air environment, so the outer side of its aluminum fins basically does not need anticorrosion, but the fin outer side of the hybrid evaporative cooler operates in humid air environment, so the fin tube bundle needs to be anticorrosive as a whole, and the overall hot dip galvanized zinc anticorrosion is generally adopted on the processed steel pipe and steel sheet. The evaporation tube section of the equipment is also very different from the tube bundle of the water cooler. The cold medium of the water cooler generally goes through inside the tube and hot medium goes through outside the tube, but the hybrid evaporative cooler is just the opposite: The hot medium goes through inside the tube, the wind and water go through outside the tube, so the outer side of the tube also needs hot dip galvanized zinc anticorrosion. Hybrid evaporative cooler is also very different from cooling water tower. Traditional cooling water tower generally has packing, but hybrid evaporative cooler has no packing in the countercurrent contact section of wind and water. Besides, cooling water tower is generally installed on the ground, while hybrid evaporative cooler is a kind of movable equipment, which can be conveniently installed on pipe gallery, platform or roof, conducive to utilizing used equipment.

0 notes

Text

COOLING TOWERS

The primary task of a cooling tower is to reject heat into the atmosphere.

Cooling tower types:

Cooling towers falls into two main categories: (1) Natural Draft and (2) Mechanical draft.

Natural Draft Towers:

Natural draft towers use very large concrete chimney to introduce air through the media. Due to the large size of these towers, they are generally used for water flow rates above 45,000 m3.hr. These types of towers are used only by utility power plants.

Mechanical Draft Towers:

Mechanical draft towers utilize fans to force or suck air through circulated water. The water falls downwards over fill surfaces which help increase the contact time between the water and the air - this helps maximise heat transfer between the two. Cooling rates of Mechanical Draft Towers depends upon their fan diameter and speed of operation.

Mechanical draft cooling towers:

Mechanical draft towers are available in the following airflow arrangements:

Counter flow induced draft.

Counter flow forced draft.

Cross flow induced draft.

Components of cooling towers:

The basic components of evoparative tower are: Frame and Casing, Fill, Cold water basin, Drift eliminator, Air inlet, Louvers, Nozzles, and Fans.

via Blogger https://ift.tt/2GBmNys

0 notes

Text

Best Wooden Cooling Tower Manufacturer in India - Cooltech

Wooden cooling tower manufacturers in India. 4900+ cooling towers successfully built in 47 years. For more information, visit Cooltech's website!

0 notes

Text

How Cooling Tower Works?

Cooling towers work by transferring heat from system water to the air, thereby cooling the water. How exactly this works depends on the system. In some systems, for example, the heated water is sprayed into the tower onto a wet deck surface. Air then flows by the water, absorbing the heat that comes off of it. The cooled water can then be released back into the facility. The airflow can be created by fans or draft towers which guide the warm air upwards because it is less dense. Some cooling towers have induced draft towers that create a vacuum on one end of the tower to cause the air to move. Hence, Cooling Tower installation is very important for factories plant.

Let's check out how many types of the cooling tower can be produced by Top Cooling Tower Manufacturers

Open loop towers

Water is distributed internally in open loop towers, sometimes referred to as open circuit cooling towers, where it immediately comes into contact with cooling air. When the air is cool, it falls into a collection basin and escapes into the atmosphere after absorbing heat from the water.

Closed loop tower

Closed-loop tower systems are meant to keep the cooling agent and the liquid being cooled from coming into touch. This indicates that the fluid can be recirculated without getting dirty. Also, since they never come into contact, it follows that the coolant and the substance don't need to be compatible.

Counter-flow tower

Utilizing opposing water and air flows, counter-flow tower systems function. As the water descends, the air ascends, absorbing the heat.

Cross-flow cooling towers

The air and water flows in cross-flow cooling towers are perpendicular. This time, the water flows down while the air is moving in a sideways motion.

0 notes

Text

Thermic fluid heater supplier/manufacturer in Maharashtra

‘DM’ series is the modular round bottle design series of Induced Draft Counter Flow cooling towers. It is equipped with a rotating distribution system, and its high-quality fiberglass provides robustness and longevity. DM series towers are highly acclaimed by industry veterans for their excellent performance and endurance. It is structurally robust to withstand harsh working conditions. . . Veda Engineering deals in Advance Cooling Towers. For more information related to products Contact us at - 7038488689 or Visit our Website - www.vedaengg.com

#manufacturing#engineering#industries#manufacturer#capitalgoodsds#industrialutilitysupplier#Thermax#vedaengg#utilitysuppliers#industrialutility#Advancecoolingtowers#coolingtower#cooling#airconditioning

1 note

·

View note

Text

Su Soğutma Kuleleri kullanışlı mı?

Su soğutma kulesi mi Chiller mi derken, soğutma kulesi kullanışlı mı sorusu kafamızda döner durur. Soğutma kulesi ne işe yarar, çeşitleri nelerdir, çalışma prensibi ve kullanımı hakkında bilgi vereceğiz. SU SOĞUTMA KULESİ NEDİR, NE İŞE YARAR ? Su soğutma kulesi; sistemden ısınarak gelen sıcak suyu bir kısmını buharlaştırıp atmosfere atarak soğutan, gerekli sıcaklığa ulaşmış kalan kısmını ise tesiste kullanılmak üzere alttaki tankta biriktiren bir ısı uzaklaştırma ünitesidir. Su soğutma kuleleri her sektörden endüstriyel tesiste ve HVAC sistemlerde soğutulmuş su elde etmek için kullanılır. SU SOĞUTMA KULESİ ÇEŞİTLERİ A. Çalışma Prensiplerine Su Soğutma Kulesi Çeşitleri Karşı akışlı kuleler (Counter flow towers) Çapraz akışlı kuleler (Cross flow towers) Karşı Akışlı Kuleler Karşı akışlı su soğutma kulelerinde su dolgular üzerinde yukarıdan aşağı süzülürken hava aşağıdan yukarı hareket eder. Günümüzde en çok tercih edilen kulelerdir. İki tipi vardır; Cebri çekişli kuleler (Induced draft towers): Fanları üsttedir. Hava, yandaki hava panjurlarından üstteki fan yardımıyla yukarı doğru çekilerek soğutma sağlanır. Cebri itişli kuleler (Forced draft towers): Fanları yandadır, hava fan yardımıyla alttan yukarı doğru itilerek soğutma sağlanır. 2. Çapraz Akışlı Kuleler: Çapraz akışlı su soğutma kulelerinde su dolgular üzerinde yukarıdan aşağı inerken hava akımı yatay veya çaprazdır. Çapraz akışlı kulelerinde cebri itişli ve cebri çekişli olarak çeşitleri vardır. B. Soğutma Tipine Göre Kule Çeşitleri Açık Çevrim Su Soğutma Kuleleri Açık çevrimlerde soğutma suyu doğrudan kule içerisindeki dolgular üzerine püskürtülerek soğuma sağlanır. Bu tip kulelerde verimlilik daha yüksektir, su ortam ile temas ettiğinden suda kirlilik olması muhtemeldir. Açık tip soğutma kulesi çalışma prensibi için tıklayınız>>> 2. Kapalı Çevrim Su Soğutma Kuleleri Kapalı tip kulelerde soğutma suyu kule içerisindeki metal serpantinler (eşanjör) içerisinde dolaşır. Eşanjör içerisindeki su, soğuk hava ve kulenin sirkülasyon suyu ile boru dış yüzeyinden dolaylı olarak soğutulur. Bu tip kulelerde soğutma suyu ortam ile temas etmediğinden her zaman temiz kalır. Dolaylı soğutma kule verimliliğini düşürmektedir. Kapalı tip soğutma kulesi çalışma prensibi için tıklayınız >>> SOĞUTMA KULELERİ NASIL ÇALIŞIR ? Karşı akışlı cebri çekişli tipteki su soğutma kulelerinde, işletmeden ısınıp gelen su, özel olarak imal edilmiş su dağıtım sistemi ve fıskiyeler yardımı ile kulenin tüm kesitine yukarıdan aşağı doğru homojen olarak püskürtülür. Püskürtülen su kütleleri, kule dolguları arasından süzülerek parçalanır. Dış ortamın nemine sahip hava, üstte bulunan motor ve fan grubu yardımı ile dolgular üzerinden aşağıdan yukarıya doğru emilir. Dolgu soğutma yüzeyinde hava ile buluşan su havaya ısı vererek soğur ve küçük bir kısmı buharlaşır. Soğuyan su kulenin soğuk su havuzunda toplanır. Toplanan su pompa yardımıyla tesise gönderilir. Suyun buharlaşması sonucu nemi artan hava (doyma noktasına yakın) kulenin en üstünde bulunan fan bacasından atmosfere atılır. Bu çalışma şekli ekli görseldeki gibidir. Islak tip kuleler dediğimiz bu kulelerde soğutma esnasında suyun bir kısmı buharlaşmaktadır. Buharlaşma Kaybı Termodinamik esaslarına göre; buharlaşan her bir gram suyun faz (hal) değişimini gerçekleştirebilmesi için yaklaşık 540 Kalori enerji sistemden emilir. Bu yaklaşımla; sistemde dolaşan suyun her 6 ºC soğuması için yaklaşık sirküle olan su debisinin % 0,9’ unun buharlaşması gerekmektedir, buna su soğutma kulesi buharlaşma kaybı denilmektedir. Bu miktar aşağıdaki formülle hesaplanabilir; Buharlaşma Miktarı (m³/h) = 0.00085 x 1.8 x Debi (m³/h) x (Tg—Tç) Örneğin; 40oC dereceden 30oC dereceye saatte 100 m3 suyu soğutacak bir kulede buharlaşma kaybı aşağıdaki gibidir; Buharlaşma Miktarı (m³/h) = 0.00085 x 1.8 x 100 x 10 = 1,53 m3/h Soğutma kulelerinde buharlaşma kaybından başka sürüklenme kaybından bahsedilir. Doğru tasarlanmış bir soğutma kulesinde sürüklenme kaybı yok denecek kadar az miktarda olur. Soğutma Kulelerinde Çalışma Prensibi Su soğutma kuleleri çalışma prensiplerine göre karşı akışlı ve çapraz akışlı kuleler olmak üzere ikiye ayrılır. Karşı akışlı su soğutma kulelerinde su yukarıdan aşağı süzülürken hava aşağıdan yukarı hareket eder. Çapraz akışlı su soğutma kulelerinde su yukarıdan aşağı inerken hava akımı yataydır. Son yıllarda karşı akışlı kuleler tercih edilmektedir. Cebri çekişli karşı akışlı tip su soğutma kulelerinde, işletmeden ısınıp gelen su, özel olarak imal edilmiş su dağıtım sistemi ve fıskiyeler yardımı ile kulenin tüm kesitine yukarıdan aşağı doğru homojen olarak püskürtülür. Püskürtülen su kütleleri, kule dolguları arasından süzülerek parçalanır. Dış ortamın nemine sahip hava, motor fan grubu yardımı ile dolgular üzerinden aşağıdan yukarıya doğru emilir. Dolgu soğutma yüzeyinde hava ile buluşan su havaya ısı vererek soğur ve az bir kısmı buharlaşır. Soğuyan su kulenin soğuk su havuzunda toplanarak işletmeye gönderilir. Suyun buharlaşması sonucu nemi artan hava (doyma oranına yakın), kulenin en üstünde bulunan fan bacasından atmosfere atılır. Termodinamik esaslarına göre; buharlaşan her bir gram suyun faz (hal) değişimini gerçekleştirebilmesi için yaklaşık 540 Kalori enerji sistemden emilir. Bu yaklaşımla; sistemde dolaşan suyun her 6 ºC soğuması için yaklaşık su debisinin % 0,9’ unun buharlaşması gerekmektedir, buna su soğutma kulesi buharlaşma kaybı denilmektedir. Bu miktar aşağıdaki formülle hesaplanabilir; Buharlaşma Miktarı (m³/h) = 0.00085 x 1.8 x Debi (m³/h) x (Tg—Tç)

https://www.susogutmakuleleri.com/sogutma-sisteminde-sogutma-kulesi-hangi-durumda-kullanilir-13.html

1 note

·

View note

Text

0 notes

Text

Water Chiller, Water Chiller Manufacturers, Forced Draft Cooling Tower

Manufacturers Of Water Chiller, Water Chiller Manufacturers, Forced Draft Cooling Tower, Mumbai, India.

FRP, FRP Cooling Tower, F.R.P. Cooling Tower, Cooling Tower, FRP Induced Draft Cooling Tower, Timber, Timber Cross Cooling Tower, Timber Cooling Towers, Timber Draft Cross Cooling Tower, Timber Counter Flow Cooling Tower, Cooling Towers, Counter Flow Cooling Tower, R.C.C. Cooling Towers, RCC Cooling Tower, Hyperbolic Cooling Tower, RCC Mechanical Draft, Chilling Plants, Chilling Plant, Mobile Close Loop Air Cooled Chilling Plant, Open Type Water Plant,Pultruded cooling towers, Open Type Brine Chilling Plant, Brine Chilling Plant, Dehumidifier, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

0 notes

Photo

CASE Jumbo Induced draft counter flow cooling towers are equipped with V Splash Bar Media Fills which make them different from other cooling towers. V Splash Bar Fills are known for their property of eliminating algae and fungi formation which is a prominent problem of wooden fills. This also eliminates the chance of any kind of rotting & clogging resulting in better performance and cooling efficiency.

0 notes

Photo

What is Counter Flow Cooling Towers?

Cooling Towers can be classified in two types. Mechanical draft and natural draft.

Counter Flow Cooling Tower is a mechanical draft cooling tower, having a CT motor mounted on the top. The fan induces the external dry air and drafts it upward. The fan exhorts the wet air back to the atmosphere.

The air moving vertically upward and water falling vertically down create the counter current to each other. Therefore this design is known as Counter Flow.

One of the main advantages of Counter Flow Cooling Tower is that the coldest water below the Fills area meets the driest air entering to the tower. This leads in enhanced performance and effectivity of the cooling tower.

www.deltacoolingtowers.in

0 notes

Text

The Steel that Warmed Us in the Night-Time ~ Chapter 2

The red bricks of the city streets of Novigrad flowed through seamlessly. It worked like clockwork with people walking around without seeking trouble; just minding their own business. One man, tailored in blue, scruffy uniform, walked quickly through the town, keeping his head down – his footsteps as fast as his heartbeat and sweat on his brow. He seemed breathless as he hurried down one street and into another, manically cutting through the sea of people that progressed throughout the morning Sun. He carried with him a heavy object in his satchel, which he held tight to his chest as if it were a magnet that could end his life if he failed his mission. After more painfully long minutes, the man ducked through a doorway and into a small building that sat on the edge of a dark, mysterious alleyway. Once he drank the cool draft that the shade gave him, he stood in the barren empty room, floorboards creaking and leaving a trail of dust from the ceiling every few seconds. Half a dozen other men, fierce as boars, circled him. One, which looked like the leader of the group, penetrated his eyes into the figure carrying the satchel.

“I’ve delivered it. Safe and sound. Not a scratch.” Although he tried to sound objective, his voice emitted a concentrated fear about him. Anxiety consumed him as 12 eyes peered at his paralysation. Each cracked their knuckles. “I’ll hand it over if you pass me the cash.” He stuttered. The leader of the pack laughed ferociously, inducing a cocky embarrassment towards the timid man in the centre. After a few more minutes, they wiped the blood off their hands and ordered the silhouette in the corner of the room to clean up the body. They swiftly left the building, satchel in hand.

Geralt and Yennefer mindlessly dawdled through a quieter area of Novigrad, carefully looking for anyone wearing something similar to the blue scruff of clothing that identified itself as their only trail to finding the amulet.

“Not a very convincing lead,” Geralt began with doubt. He was worried that, in a town this large, they would stand no chance locating some sort of clue.

“Just keep searching,” Yennefer replied with boredom, “the quicker we get this finished, the quicker I can have a drink.” It seems that Geralt spoke too soon as immediately someone wearing the same colour blue bumped passed them with a small amount of force. A large, muscly man followed by five others all heading in the same direction. Relaxed. The force of collision revealed a purple glint inside the satchel he was carrying… the amulet! Both Geralt and the men pursued in the swift run, but each blue-wearing target had all split off on their own. Amusingly, this made Geralt’s pursuit easier! He followed the man with speed, trying not to drown under the pressure of the people that blocked his path. Bins were knocked, trolleys were thrown and market stalls crashed over the reckless weight of the pursued and the pursuer. Screams started to occur as the realisation of the chase became notorious. Geralt’s vision centred on the man, making sure he did not escape. It didn’t take long before Yennefer screamed his name as he ran into a heavy fruit stall that peered around the corner. Everything went black.

*

Ciri sat in a dimly lit tavern, warmth all around, trying to eavesdrop on a few people that occupied a table behind her. It wasn’t long until she concluded that they were not talking about a precious amulet – only about what they’re going to do at the weekend, and such. She waited a moment longer before standing up and darted to the door disappointed. Only a few steps before the door however that a panting, out-of-breath man entered with a rough, torn brown bag on his shoulder. He was wearing a similar blue costume to the one Geralt and Yennefer talked about earlier whilst she was eavesdropping. Her eyes became more alert like the ears of a cat. After an attempt to blend into the surroundings whilst tailing the gentleman, Ciri followed him up some narrow stairs and onto the second stage of the building. The room she entered contained three shady-looking men in more, similar tattered uniforms. The room felt dark as if some very nasty things happened in them. Some of the windows were heavily boarded up with wood and nails, and the room had a tingly, metal smell which was static and stale. Dust fogged her vision greatly, encouraging a gloomy atmosphere. She stepped confidently into the centre of the room in which she stood on a recent bloodstain that clothed a section of the flooring.

“I believe you have something of mine.” She broke the silence.

“You don’t belong here.” The man threatened, his back facing her. His voice grumbled like gravel stones, hoping to conduct intimidation.

“Fine. I gave you a chance. Guess we’ll have to do this the hard way.” Ciri drew her sword from her metal casing which was strapped to her back; a metal twang sang in the silent, misty air.

*

Geralt awoke. Shit.

“It’s okay!” Yennefer consoled. Geralt reconstructed his knowledge of his current surroundings. Yennefer had dragged his body into a quieter and darker alleyway to rest. He hadn’t been out for long as it was only midday according to the Sun that peeked over the thin opening above them. Yennefer knelt over him as he lie flat on the hard, rocky ground. The ground was wet and was coated in spots of wet puddles and littered packaging. “Sorry it wasn’t the most luxurious of conditions.” She giggled. It took a few minutes to get back to the main street. Geralt was frantically cursing as they walked through the crowd because they lost the only lead.

“How are we going to find it now?” he moaned through clenched teeth. Evidently, he was annoyed – even the raven-haired sorceress saw through that! Amusingly, immediately as he swore some more times, they heard windows shattering; shouts and screams coming from a sparse street to their left. It didn’t take much convincing until they were headed full speed down it. A few dodges here, some crawls there. To avoid a large amount of embarrassment, Geralt carefully traced to the building without running into any more obstacles. When they reached the building, more clatters occurred. More wooden boards and shattered glass fell which almost hit them. Geralt led the way as they ducked inside.

*

Cirilla blocked the incoming attacks like elegant swimmers, making it look effortless even though she took a few slices to the shoulders. The three men were more difficult to kill than she thought as all six legs were still standing. They reached a stand still. Their swords still poised upright and eyes locked into position, slowly making their way around the room in stance. They were focused so much that when a Witcher and sorceress burst through the door with a large amount of force, they all jumped unexpectedly. For a moment, Geralt and Yennefer were undecided whether to be shocked of Ciri’s presence or to protect her from the invading hostilities.

“What the hell are you doing here?” he roared drawing his sword.

“Shut up and help me!” Ciri replied, stabbing at the nearest attacker. Blood papered the walls, solidifying in small, gruesome bits across the interior wood. Slices of swords littered the next few seconds. The first man fell, then another. Three faced the last, nervous filled man. He backed away, clutching the amulet. Mercilessly, Ciri ferociously kicked the man forcefully through a glass window behind him. The glass smashed into tiny fragments as his body thumped on the now bloody ground below.

Deep breaths consumed the dust-clogged air. They could hardly wait to get out of this rich, blood stained room.

“Well. This is awkward.” Cirilla stared at Geralt, and he stared back, frustrated.

“You were supposed to stay at the castle!” he said through clenched teeth, restraining from raising his voice.

“Well, I guess I just couldn’t help myself.”

“Stop it, both of you!” Yennefer interrupted. She tried to have more concern over their argument but seemed more frustrated with the blood stain that dried on the cuff of her clothing. She tugged at it multiple times, “let’s just get this amulet and get out of here.” They agreed. When Geralt dragged his stiff legs over to the windowsill, he growled and cursed.

“What?” Ciri noticed.

“The amulet may have fallen down with the glass-pricked corpse down there…” he whispered under his breath. Leaning over, he saw the lifeless corpse huddled around by bystanders. Swiftly, Geralt caught a peasant in a tweed, rough jacket snatch the bag and then retreat in a hurriedly way.

“Shit!” he cursed again, “I’ll deal with these two whilst you two run after him.” He pointed to the other still bodies. Without a word, Cirilla and Yen bolted out of the broken-latched wooden door and down the stairs. As they burst out of the door of the tavern after an odd look from the bartender, they saw that the man with the treasure had broken into a run – realising that a sword and various torturing spells were bolting after him. Pushes and dodges occupied the scene for a surprisingly long amount of time as they realised that the thin, poor man was skinny and quick. They countered moving stalls, flinging doors and idled people that waltzed down the street in the opposite direction. His heart must’ve skipped a beat when he looked at the ashen-haired women who was on his tail and looked as furious as the devil’s daughter. Finally, he was unconscious on the floor, oblivious to what had happened. Ciri lie with him, panting from the magnificent dive she had just performed. Yennefer elegantly picked the brown satchel up, checked the amulet was in there, and then slung it over her shoulder.

“Well, that’s that then.” Ciri struggled to emit the words. “What now?”

“Long way to go, yet. We’ve got to retrieve another eight of these.” Yennefer exhaustedly said. “Come, let’s find our White Wolf.”

Thanks for reaching the end of this chapter! I’m still incredibly thankful that people are still interested with the content I produce. It was literally a test to see if I could write anything about my favourite book and game franchise - then boom; I might have found a hidden talent! I hope you are still enjoying it. Please leave me any feedback or ideas for the next season; DM me! :)

Link to Chapter 1: https://thealfanator.tumblr.com/post/161443706234/the-steel-that-warmed-us-in-the-night-time

#the#steel#that#warmed#us#in#night#time#chapter#two#geralt#of#rivia#butcher#blaviken#yennefer#vengerberg#ciri#cirilla#witcher#rise#white#wolf#assassin#kings#wild#hunt

9 notes

·

View notes

Link

Tower Tech Cooling Towers offer Round and Bottle cooling tower Worldwide. Round/Bottle Cooling Tower is made from Counter Flow-Induced Draft Technology. Know more about the stand-out features of the bottle cooling towers.

0 notes

Link

0 notes